PCB assembly is usually outsourced by OEMs to a specialized manufacturer, as assembling a printed circuit board unit needs a large investment. There exist hundreds of small components which help complete the circuit in a PCB. Almost all small businesses frequently need the services of a contract manufacturing company to source their PCB units.

The modern technology of PCB Manufacturing is now more complex as manufacturers have initiated offering printing. PCBs are widely-used to support and join up electrical parts mechanically. They are cheap and are also intended for the high-volume manufacturing. Before making a PCB, manufacturers determine its design remotely. At this point, a PCB prototype will play the essential role in the development of its design and enables the manufacturer to anticipate when anything must be fixed in the PCB’s design. For any malfunction in the prototype, a new prototype is made and is kept under custody until finally it works well.

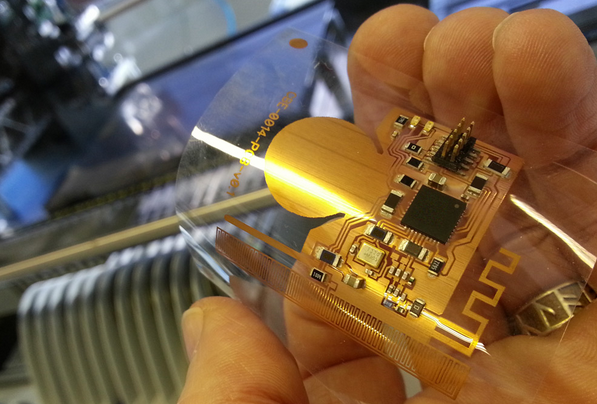

The process of PCB Creation will go under extreme factors and many steps are needed , like etching , engraving pictures , multi-layer processing , drilling , finishing, masking , last of all testing . PCB Test is conducted to find out its performance and make sure that it performs what it is expected to do. Some vendors use various types of PCB specifications to make it work, as needed, such as utilizing polyimide for versatility, Arlon for life-extending in high temperature, and also Isola range for PCB prototype. Nevertheless, when the PCB Test appears to be bad, then the whole circuit board might be replaced or repaired immediately.

Dealing with PCB Assembly, this is when electrical components are connected with a circuit board; we name it as PCB Assembly. To join such electronic components to the PCB, many methods are used and 2 major methods are, surface mount technique and also through-the-hole method. However, in the majority of the circuit boards, both such methods are put together, to attain optimum efficiency in the performance and design of the PCB. However, sometimes manufacturers use quite skilled professionals to solder small components using microscope. In addition they use other tools like tweezers, soldering tip, and so on.

For a PCB to be complete, not only tools are essential, but also PCB Manufacturing, PCB Assembly and Test. Therefore, everything really needs proper attention. So, when selecting PCB manufacturer, conduct an in depth research regarding the company, its track record, so you get reliable and top quality services in return.