If you currently own or manage a business, it is likely that you’ve heard of a closed-loop economy model. Whether or not you believe in the many benefits that other organizations have found through this model, it is important to understand how this model works and how it can be incorporated into your organization. Luckily, this post and the coupled infographic will detail exactly how this model functions, in addition to how it can positively impact your organization.

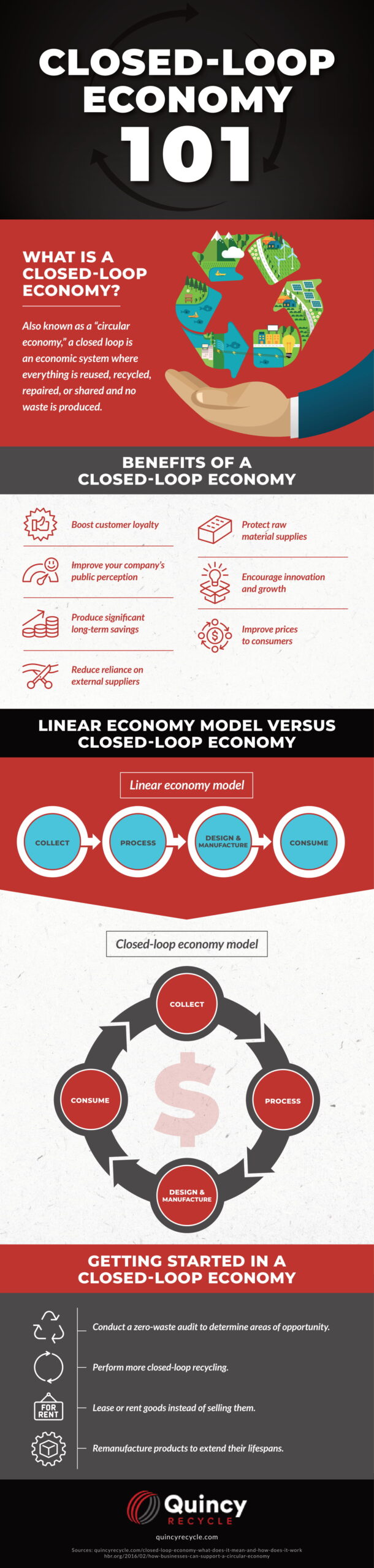

First things first, though, the nomenclature of these economic models can be a bit confusing. To clarify, a closed-loop economy is synonymous with a circular economy and a closed-loop supply chain. Meaning these models all prioritize reducing the amount of waste that is created throughout a product’s life cycle. In these models, every input and output is reused, recycled, shared or repaired. Rather than wasting inputs and outputs that might be considered no good, they are utilized in some shape or form to create value in the form of a substance or product in a closed-loop model.

In recent years, this model has seen quite the rise in popularity. In fact, as popularity continues to grow, estimates suggest that by 2030 this model will be worth $4.5 trillion dollars globally. While majority of businesses don’t operate worldwide, there are still an incredible number of benefits that can be realized by businesses through proper integration of this strategy. Some of those benefits include an increased sense of customer loyalty, a healthier public recognition as a result of green initiatives, and even a decrease in the dependency organizations have on external suppliers. Also worth noting, is when more and more businesses transition into this strategy, the harm done on the environment is reduced as a result of more and more raw material being saved and being reusable. This greatly benefits businesses and their customers.

Closed-Loop Economy In Action

For organizations hoping to transition and operate under a closed-loop economy, they’ll first need to work toward establishing a closed-loop supply chain. In most cases, that means the fundamental processes of an organization will have to be rethought and retooled. One of the prime examples of this is typically found in the way that organizations package their products. The design and manufacturing processes for the packaging of their products will have to be completely revitalized in order to conserve the materials used in the process. After these processes are reworked, organizations will have to consider how the sale, refurbishment, and recyclability of their products correlates to their design and manufacturing processes. Ideally, as more and more businesses begin operating under a closed-loop economy, the easier it will be to preserve and reuse the raw materials used in each of these processes.

The problem is that a majority of companies currently follow a more linear economy model. Meaning the raw materials used in the production processes of their products are often wasted. In turn, this means any new products that must be created have to be done so through fresh raw materials. This is the overarching benefit of a closed-loop economy: there is no endpoint or waste. Having a cyclical nature means businesses are able to reuse their consumed raw materials by reprocessing them rather than acquiring new raw materials. This results in the most sustainable product for customers, in addition to the most sustainable model for the environment. For additional information on how this model operates, be sure to view the featured resource coupled with this post. Courtesy of Quincy Recycle.