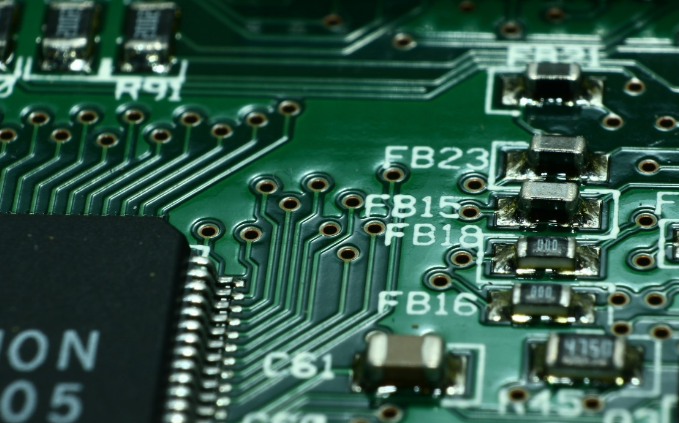

Getting that PCB of yours made is no simple accomplishment, and there’s a boat heap of apparatus, human work, and cycles that make everything occur. Be that as it may, your rundown of concerns are presumably extraordinary and include getting your load up back in an opportune way while setting aside some cash simultaneously.

That is the reason we’re here, to assist you with dodging the superfluous intricacy and mistakes in your PCB plan that can remove a gigantic sum from your wallet come producing time. So right away, here’s 10 commonsense tips that we set up that are ensured to get a good deal on your next outing to the fab house.

To start with, this guide is outfitted towards the entirety of our marvelous specialists and producers out there that are simply wandering out into the universe of PCB fabrication. We will not cover anything very mind boggling here identified with fast plan impedances, daze/covered vias, and so forth

Tip 1. Minimum Board Size Recommended

While this one may be the most self-evident, it’s additionally the one factor that can remove an immense piece from your wallet. Continuously attempt to downplay your finished board size, as the greater it gets, so do your expenses. This likewise works the reverse way around.

On the off chance that you make your board too little, a producer will require exceptionally exact hardware to assemble everything put, which will likewise cost more. So toward the day’s end it’s a difficult exercise for you to explore among size and unpredictability, yet attempting to decide in favor of toning it down would be best.

Tip 2. Don’t Skimp on Quality Materials

Before you proceed to advise your maker to utilize one of those less expensive, substitute materials for your layer stack, listen to us. Consider when you get that board back, imagine a scenario where it fizzles inside the space of days, weeks, or months after you power it up.

On the off chance that you hold back on materials now, you’ll likely end up losing more cash over the long haul when you find that your sheets are celebrating espresso napkins. So with regards to choosing materials for your layer stack, utilize the norm, quality stuff, it’s there which is as it should be.

Tip 3. Stick with Standard Board Shapes

Except if you have an insane looking wall in the area to accommodate your plan in, consistently plan your board in the standard square and rectangular shapes normal for most Prototype PCB

Doing anything strange will soar your assembling costs essentially. Likewise, try not to add any inner patterns to your PCB except if you need it to mount to a wall in the area. Keep it basic!

Tip 4. Minimum Spacing Recommended

This one works the polar opposite of your board size. As the dividing between your copper objects like cushions and tracks diminishes, the more your assembling costs will increment.

The thinking behind this is genuinely straightforward, the more stuff you pack into a more modest bundle, the more exact the assembling apparatus should be. Numerous fab houses have a standard arrangement of dividing prerequisites, which is somewhere near 8-10 mils least dispersing between cushions, tracks and track widths.

Tip 5. Holes with Biggest Diameter Possible

The more modest your openings and annular rings, the higher your assembling costs will climb. Once more, it boils down to more modest dispersing requiring exact hardware. Numerous fab houses will even charge extra in the event that you need openings that are more modest than 0.4mm, so make certain to call your maker to maintain a strategic distance from any superfluous expenses.

Tip 6. Use Right Via

There are three kinds of vias – through-opening vias, dazzle vias, and covered vias. The last two are simply going to be utilized for high thickness and high recurrence PCBs. So this one is straightforward, if your plan needn’t bother with these kinds of vias, forget about them to keep away from any additional assembling costs.

Tip 7. Chill Out with Extra Layers

Before you go adding a lot of extra layers for seriously steering space, power planes, or execution, reconsider.

The contrast between a four layer board and a two layer board is twofold! On your next plan, keep things perfect and conservative and just use however many layers on a case by case basis to take care of business. Regardless of whether that implies somewhat more in board size.